Not many people give a lot of thought to their tyres and see them as just another element of a car. Fleet Managers, however, understand how important it is to have OE (Original Equipment) fitments and to select the right tyre for the right terrain. For that reason, many organisations have detailed risk assessments that outline their fleet tyre replacement policy.

With the rollout of electric vehicles across fleets, using tyres designed for purpose is increasingly important for the proper maintenance of your fleet. Goodyear has developed new subcategories in tyre technology, known as FACE (Fleets, Autonomous, Connected, Electric), and are increasingly using technology to remain relevant with OE customers.

Most tyre manufacturers are now developing OE tyres that are specifically engineered to suit the performance and dynamics of electric vehicles. They may still look the same, but they have many different considerations when compared with an ICE vehicle. Size, load and speed rating are no longer the minimum criteria for a replacement tyre.

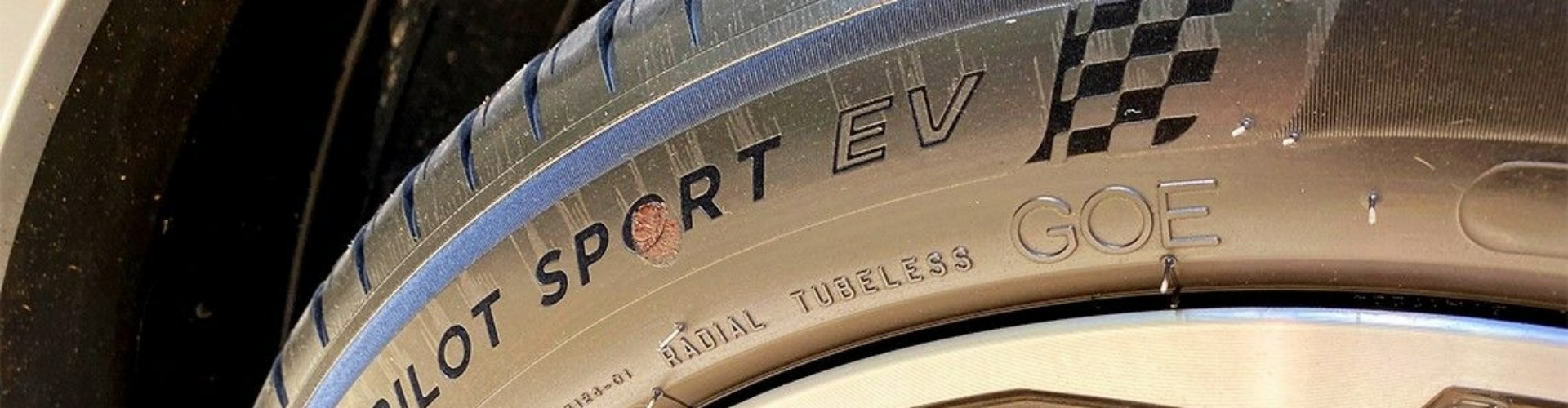

You can tell the difference because vehicle manufacturers have now developed a coding system, which the tyre manufacturers must include on the sidewall of the tyre. Some examples are: AO, MOE, MO, VOL, HN, RO1, TO.

So, let’s take a look at how tyres for electric vehicles are different.

Electric vehicles don’t generate engine noise so the only sound you’re likely to hear inside the cabin is the tyres on the road. So, when designing EV tyres, the goal is to reduce as much noise as possible. Tyre manufacturers do this with sophisticated tread designs and low noise rubber compounds.

Supporting the vehicle load is one of the basic roles performed by a tyre. They also deliver the power from the drivetrain to the road for acceleration and absorb the forces when the brakes are applied. Each of these functions will be different with heavier electric vehicles, which deliver more torque to the wheels.

This means that tyres for EVs need to be stronger. They need to carry more load and handle greater forces when accelerating, braking and turning corners. If tyres designed for petrol- or diesel-powered cars are fitted to an EV, they’ll affect the vehicle’s safe operation, and wear out quicker, which will then increase your running costs.

When every kilowatt counts to get you to your destination, you need tyres that won’t hold you back. Electric vehicles use low rolling resistance tyres to help increase range and reduce the energy used to keep the car moving.

Low rolling resistance tyres were originally developed to help vehicle manufacturers achieve lower emissions with ICE vehicles. The less effort needed to get the car going and keep it moving, the less CO2 is produced by the engine.

To build tyres that roll better, manufacturers start by reducing the weight of the tyre. Michelin launched a Pilot Sport EV in 2021 that was 2.1kg lighter than the Pilot Sport 4 SUV. They estimated it’d increase the range of an EV by more than 10%.

When cars and tyres were first made in Australia, it was a one size fits all situation. This kept costs down for manufacturers and stopped competition from cheaper imports. This has now changed, and the diversification of fleet vehicles has made budgeting for maintenance and tyre expenses more complex.

OE branded tyres for electric vehicles will usually cost more. For example, a Tesla Model 3 has Michelin tyres fitted as original equipment in the size 235/45R18. The Michelin Pilot Sport 4 non-Tesla tyre sells for approximately $300. The Michelin Pilot Sport 4 tyres marked with the Tesla TO coding retails for $387.

Even non-EV OE marked tyres cost more than their generic cousins. There are many reasons for the difference in price, including research and development costs and sales volume. Especially for fleet vehicles, though, the risk of using generic tyres doesn’t seem worth the benefit of saving a few dollars.

Maybe it does for ICE vehicles, but with semi-autonomous, connected, electric fleet cars, where every part of the design has a purpose to maximise range, probably not. If you’re keen to invest in EVs for your fleets, you might as well get the optimum performance out of them and use OE tyres that will go the distance.